|

Pollution as disease force multiplier?

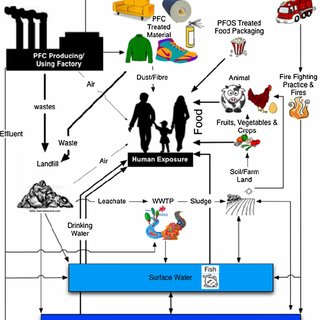

Forever chemical Pollution - Immune systems low in key areas of Co-Vid outbreak - cause and effect?

Presented here is a link hop - what i hope to suggest is that

the Viral outbreak has gained traction due to local populations

Immune systems being compromised after exposure to FOREVER CHEMICALS.

Yes i know we can't really trust the numbers of Co[n]vid deaths etc

but i thought it would be interesting to try and find out if their was a correlation between PFAs etc with the initial/central outbreak areas

|

|

March 27, 2020 -

As the new coronavirus explodes in cities across the U.S., public health agencies and hospitals are making testing-which was initially plagued by significant shortages-increasingly available. And biotech companies are ramping up production of test kits—but states are still struggling to meet demand.

CR-based tests are being rolled out in hospitals nationwide, and the Food and Drug Administration is fast-tracking novel approaches as well...

|

SARS-CoV-2 Coronavirus Multiplex RT-qPCR Kit

Regulatory status: For research use only, not for use in diagnostic procedures. non-specific interference of Influenza A Virus (H1N1), Influenza B Virus (Yamagata), Respiratory Syncytial Virus (type B),

Respiratory Adenovirus (type 3, type 7), Parainfluenza Virus (type 2), Mycoplasma Pneumoniae, Chlamydia Pneumoniae, etc.

but the test has limitations

Limitations

The detection result of this product is only for clinical reference, and it should not be used as the only evidence for clinical diagnosis and treatment. The clinical management of patients should be considered in combination with their symptoms/signs, history, other laboratory tests and treatment responses. The detection results should not be directly used as the evidence for clinical diagnosis, and are only for the reference of clinicians.

The detection result can be affected by operations, including specimen collection, storage and transportation. False negative result may occur if there is any mistakes in the operation. Cross contamination during specimen treatment may lead to false positive result.

The detected target sequences of this products are the conservative region of 2019-nCoV's ORF1ab gene and N gene. However, target sequence variations may lead to false negative result.

|

|

|

Rick Birkmeyer grew his first biotech company, Strategic Diagnostics Inc., from a handful of employees into a publicly traded company with $30 million in annual revenue before he left more than a decade ago.

Quote: on joining CD diagnostics

"When I joined this company it was because their initial work was interesting enough for me to say,

Hey this is a big market with an unmet need,'" he said. "So I decided I should join them and see what I can do."

|

interestingly Creative Diagnostics is a partner of this company

a genomics services company, innovates sequencing services as well as genotyping and library construction to develop integrated systems of genomic products and services.

With professional work team and advanced biotechnology, the company has already been selling products in the United States, Europe, Asia. Scientists from CD Genomics have participated in many genome projects, such as Illumina,[1] the genome sequence,[2] DNA analyzer,[3] Bacillus thuringiensis, Thermoanaerobacter tengcongensis, Streptococcus suis, and quite a few virus genomes.[4]

CD Genomics provides viral genome sequencing service within Illumina and PacBio Platforms. We can create high-quality de novo assembly of large viral genomes and highest possible data quality at low cost.

|

|

|

interestingly the CEO of creative diagnostics is Rick Berkmeyer

who used to work at Dupont

"One of the things that I did while I was at DuPont was a two-year stint in each department," Birkmeyer said. "The roles change. Therefore, there are times the personality of a CEO might fit at one stage and then another stage."

|

|

|

Dupont Gave CD dignostics CEO a start up grant to form Strategic Diagnostics

"When I was working with DuPont, one of the groups that was part of DuPont at the time was Conoco Oil. They had spent $17 million developing a little rapid test that looks

much like a home pregnancy test kit. It was for bacteria that was found in oil wells that very quickly could eat through a stainless shaft and cause that well to go down for days.

They wanted a test that could very quickly say: "Is this bacteria present so that we can treat this well with biocide?" Within DuPont, they spent the $17 million developing this test. They brought it to my group to manufacture it, and lo and behold, they found out that the product couldn’t be frozen and had to be refrigerated. Well, that’s a real problem when your market is Abu Dhabi and the north slopes of Alaska. So, I convinced them to support me, give me a grant, move outside of DuPont, and start up my first company, Strategic Diagnostics. So, that’s how I got started."

|

|

THE DOW AND DUPONT MERGER

"...if Monsanto and Bayer, the 1st and 3rd largest biotech and seed firms, together with Dow and DuPont being the 4th and 5th largest biotechnology and seed companies in the world respectively, both went through with the mergers, the so-called "Big Six" in the industry would control 63 percent of the global seed market and 76 percent of the global agriculture chemical market. They would also control 95 percent of corn, soybeans, and cotton traits in the US. Both duopolies would become the "big two" industry dominators.

The merger formed the world's largest chemical company in terms of sales. DuPont is headquartered in Wilmington, Delaware."

|

|

POISONING THE ENVIRONMENT

in DUPONTS own words

Litigation: The Company is party to a number of claims and lawsuits arising out of the normal course of business with respect to product liability,patent infringement,employment matters, governmental tax and regulation disputes, contract and commercial litigation, and other actions.Certain of the claims and lawsuits facing the Company purport to be class actions and seek damages in very large amounts. All such claims are contested.

With the exception of the possible effect of the asbestos-related liability of Union Carbide Corporation ("Union Carbide") and Chapter 11 related matters of Dow Corning Corporation ("Dow Corning") as described below, it is the opinion of the Company's management that the possibility is remote that theaggregate of all such claims and lawsuits will have a material adverse impact on the Company's consolidated financial statements.Union Carbide is and has been involved in a large number of asbestos-related suits filed primarily in state courts during the past four decades.

|

|

At December 31, 2017, Union Carbide's total asbestos-related liability, including defense and processing costs, was $1,369 million ($1,490 million at December31, 2016).In 1995, Dow Corning, a former 50:50 joint venture, voluntarily filed for protection under Chapter 11 of the U.S. Bankruptcy Code in order to resolve breastimplant liabilities and related matters ("Chapter 11 Proceeding").

Dow Corning emerged from the Chapter 11 Proceeding on June 1, 2004, and is implementing the Joint Plan of Reorganization (the "Plan"). The Plan provides funding for the resolution of breast implant and other product liability litigation covered by the Chapter 11 Proceeding and provides a process for the satisfaction of commercial creditor claims in the Chapter 11 Proceeding.

At December 31, 2017, Dow Corning's liability for breast implant and other product liability claims was $263 million ($263 million at December 31, 2016) andthe liability related to commercial creditor claims was $78 million ($108 million at December 31, 2016).See Note 16 to the Consolidated Financial Statements for additional information on these matters.

Environmental Compliance:

The costs of complying with evolving regulatory requirements could negatively impact the Company's financial results.Actual or alleged violations of environmental laws or permit requirements could result in restrictions or prohibitions on plant operations, substantial civil or criminal sanctions, as well as the assessment of strict liability and/or joint and several liability.

The Company is subject to extensive federal, state, local and foreign laws, regulations, rules and ordinances relating to pollution, protection of the environment, greenhouse gas emissions, and the generation, storage, handling, transportation, treatment, disposal and remediation of hazardous substances and waste materials. At December 31, 2017, the Company had accrued obligations of $878 million ($909 million at December 31, 2016) for probable environmental remediation and restoration costs, including $152 million ($151 million at December 31, 2016) for the remediation of Superfund sites.

This is management's best estimate of the costs for remediation and restoration with respect to environmental matters for which the Company has accrued liabilities,although it is reasonably possible that the ultimate cost with respect to these particular matters could range up to approximately two times that amount. Costsand capital expenditures relating to environmental, health or safety matters are subject to evolving regulatory requirements and depend on the timing of thepromulgation and enforcement of specific standards which impose the requirements. Moreover, changes in environmental regulations could inhibit orinterrupt the Company's operations, or require modifications to its facilities.

Accordingly, environmental, health or safety regulatory matters could result insignificant unanticipated costs or liabilities.

Health and Safety: Increased concerns regarding the safe use of chemicals in commerce and their potential impact on the environment as well as perceived impacts of plant biotechnology on health and the environment have resulted in more restrictive regulations and could lead to new regulations.

Concerns regarding the safe use of chemicals in commerce and their potential impact on health and the environment and the perceived impacts of plant biotechnology on health and the environment reflect a growing trend in societal demands for increasing levels of product safety and environmental protection.

These concerns could manifest themselves in stockholder proposals, preferred purchasing, delays or failures in obtaining or retaining regulatory approvals, delayed product launches, lack of market acceptance and continued pressure for more stringent regulatory intervention and litigation.

These concerns could also influence public perceptions, the viability or continued sales of certain of the Company's products, the Company's reputation and the cost to comply with regulations. In addition, terrorist attacks and natural disasters have increased concerns about the security and safety of chemical production and distribution. These concerns could have a negative impact on the Company's results of operations.

|

IS DUPONT LAYING OFF KEY INFRASTRUCTURE WORKFORCE AND

THIS ARTICLE TALKS ABOUT FORMER DUPONT WORKERS MAKING THEIR OWN COMPANYS AFTER DUPONT 'LAYOFFS'

"When it spun off its former performance chemicals unit in 2015, DuPont was facing multidistrict litigation involving 3,500 personal injury claims related to PFOA. DuPont pegged the maximum liability for those cases at $128 million. Dupont settled 19 months later for $671 million, agreeing to pay half the settlement amount, and up to $125 million more toward costs of other PFOA-related litigation. Chemours paid the other half.

Chemours claims that DuPont had "a keen incentive" to downplay environmental liabilities while extracting a multibillion-dollar dividend from Chemours that would help fund a stock buyback. Chemours sought a declaratory judgment from the court limiting DuPont’s indemnification rights to the maximum liabilities it certified, or for an order directing the return of the $3.9 billion dividend."

PFAS chemicals have caused contamination problems in drinking water supplies in cities and towns across the nation and are now the subject of numerous lawsuits.

Since the 1940s, DuPont made and used PFAS chemicals to make highly profitable consumer products, including Teflon, which at one point earned $1 billion a year for the chemical giant. Communities whose water is contaminated with the Teflon chemical, or other PFAS compounds from other companies, face huge costs for installing filters to remove the chemicals, which have been linked to cancer, thyroid disease, reproductive and immune system problems and many other serious health harms.

USA: New York state sues Chemours, Dupont, 3M for alleged

contamination of drinking water by toxic substances

"claims toxic substances in the manufacturers’ products, specifically foam used for firefighting, threatened public health and damaged the state’s natural resources...

The aqueous film-forming foam, known as AFFF, contains per- and polyfluoroalkyl substances, or PFAS, including PFOS, a type of PFAS commonly found in contamination from the use of firefighting foam...

New York’s legal actions follows on the heels of similar lawsuits against chemical makers from other states, including New Jersey, New Hampshire, and North Carolina..."

[snip]

The complaint alleges that DuPont, Chemours, and the manufacturers should have known that AFFF products and PFAS would "very likely injure and/or threaten public health and the environment."

The companies also should have known that the products dissolve easily in water, have long shelf lives, and tend to bioaccumulate in the blood, meaning they can build up and stay in the blood of the general population, according to the complaint.

"On information and belief, Manufacturers’ and DuPont/Chemours’ conduct involved actual malice or wanton, willful, and reckless disregard for the health, safety, and rights of others. The Court should award the State punitive damages in an amount sufficient to deter and punish such conduct," the complaint says.

Northern Italy is showing the highest in numbers for "Co-Vid 19"

"The number of cases has increased rapidly because there are two hotbeds, among other things, linked to two hospitals, and we have learned from SARS that these viruses spread mainly in nosocomial [originating in hospital] environments,» explains Giorgio Palù, professor of microbiology and virology at the University of Padua, and an internationally-renowned expert.

"Besides, northern Italy has communications with China every day because there are fairs, industries, relocated industries, and people travel a lot."

"The city of Vicenza is about 30km from Vo', a small settlement of 3,000 inhabitants that ended up on the news globally when one of its fellow citizens, 78-year-old pensioner Adriano Trevisan, became the first victim of coronavirus. "

EU Observer

Via WHO special report

"The discovery of PFAS water contamination in the Veneto Region, which was both complex and severe, was undoubtedly a testing moment for both the institutions and the population of the Veneto Region. "

11 September 2018

Italy pneumonia due to Legionella?

"Legionella, the bacteria that causes Legionnaires' disease and other illnesses, has been confirmed in at least 12 of around 200 cases of pneumonia in Brescia, northern Italy, authorities said on Tuesday."

"There is no reason to close schools or not to drink tap water," he assured, adding that most of the patients affected were either elderly or had weakened immune systems. Separately, a suspected legionella infection was reported on Tuesday in Turin, where a woman in her 60s and suffering from other health problems died in hospital with symptoms of pneumonia. Health authorities are investigating, according to Ansa, which reports that she may have picked up the bacteria while on holiday at the coast.

Italy

Dow was established in Italy in 1960. A key player of the local chemical industry, Dow can count on a solid structure with its headquarters in Milan, a global R&D center in Correggio for Polyurethanes and four industrial production sites: Correggio (Polyurethanes systems), Mozzanica (Water-based acrylic emulsions), Mozzate (Polyurethanes and specialty resins for the production of adhesives), Parona (Polyester resin adhesives).

source

Subsideries in Italy

Danisco Italy S.p.A.

Hops, malt and raw material suppliers

Raw materials (1025 Companies)

Raw materials for non-alcoholic beverages production (680 Companies)

Fruit extracts (43 Companies)

Fruit juice concentrates, beverage concentrates (263 Companies)

Flavours (161 Companies)

clicking on this link redirects to here [CAUTION SICKENING PR]

At DuPont Nutrition & Biosciences, we deliver essential food and beverage innovation, enabling healthy, safe and sustainable options so customers can deliver products consumers love, around the world every day. Through deep consumer insights and market knowledge, strong technical expertise and problem-solving capabilities and our broad DuPont™ Danisco® range, we know It’s What’s Inside that can create the best solutions for you.

For decades, our DuPont™ Danisco® range of ingredients has provided improved nutritional profiles, better taste and texture, and greater cost efficiency to meet the needs of global food and beverage, dietary supplement and pet food manufacturers. Through the work of a global network of food scientists and technologists at DuPont, the Danisco® range is supported by a uniquely broad spectrum of know-how across applications and market segments.

Performance Specialty Products Italy S.r.l.

Location:

Milan Area, Italy

Advanced Printing at Performance Specialty Products Italy S.r.l.

but here it describes

Probiotics, personal protection devices, systems for the supply of clean water, smarter and faster electronics and much more: we use science to innovate, to create many important products and solutions for daily use. At DuPont, we are working to make the world a safer, healthier and better place.

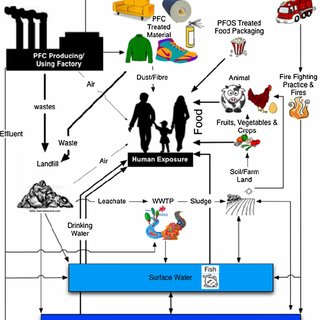

For decades prior to 2013, the people living in 21 municipalities in the south-west of the Veneto Region, Italy, were unaware that the tap water they were drinking contained perfluoroalkylated substances (PFAS). The contamination was affecting the groundwater, the surface water and the drinking-water. PFAS are highly resistant persistent compounds used for repelling oil, grease and water and protecting the surfaces of carpeting and clothing; they are also contained in fire-fighting foam. They have been found to have negative consequences for human health, such as pregnancy complications, thyroid disease, high cholesterol, and cancer, though these are not fully established. This case story describes the experiences of the Veneto Region in managing PFAS contamination in its waters. It provides a snapshot of the situation prior to the discovery of the contamination in 2013 and describes the short-, medium- and long-term steps taken to deal with it up to spring 2017

[SNIP]

From the 1950s until the early 2000s, the chemical plant, DuPont Washington Works, in southwest Parkersburg, West Virginia, USA, released C8 into the air and the Ohio River. C8 is a surfactant for polymerization of tetrafluoroethylene (TFE) used to produce polytetrafluoroethylene (PTFE), or Teflon. PFOA in these emissions reached drinking-water supplies by entering the groundwater where it was detected in six districts near the DuPont plant in 2002. Air emissions from the plant have been largely eliminated, as have any significant releases into the Ohio River. Carbon filters are used to remove C8 from nearby water systems.A class-action lawsuit against Dupont ended in a settlement, which involved: • carrying out a supplies’ clean-up;• conducting a biomonitoring survey; • establishing a C8 science panel, including international experts.

A biomonitoring survey, called the C8 health project, was conducted between August 2005 and July 2006. Information was gathered through interviews and questionnaires, and blood samples were collected from about 69 000 people living near the plant. The C8 health panel found six probable cause–effect links, namely between C8 and pregnancy-induced hypertension/preeclampsia, autoimmune ulcerative colitis, thyroid disease, cancers of the testes and kidney, and increased cholesterol (1

[SNIP]

identification of PFAS contamination;

During the spring of 2013, following the results of a IRSA–CNR study (20), the Regional authorities were alerted about the presence of PFAS in the groundwater, surface water and drinking-water in some parts of the Veneto Region. The area involved spanned more than 200 kms2. Studies carried out by the Regional Environmental Protection Agency showed two main pathways for the spread of the contamination: (i) wastewater from the factory responsible for the pollution, which was emitted into a creek and percolated into the ground-water system; and (ii) water from a wastewater-treatment plant connected to the factory; this wastewater was deposited into a canal that drained into a river, the high flow rates of which enabled PFAS to be transported over long distances.

[SNIP}

The Regional Environmental Protection Agency took the lead in carrying out a series of environmental monitoring actions in 2014–2016. In August 2014, a preliminary evaluation of local food products revealed contamination in some categories, such as eggs from locally bred hens and fish from contaminated rivers, that could affect the health of the consumers. The Region’s drinking-water monitoring system was reorganized and procedures to manage PFAS concentrations above the threshold value were established. The monitoring system included not only drinking-water but also other environmental matrices, such as surface water, groundwater, soil and air; thus, a comprehensive PFAS data warehouse was created for all water sources. Moreover, an environmental early-warning system was set up to identify key water-sampling points that should be regularly monitored.

The selection of water-sampling points was systemized and the drinking-water network re-evaluated according to the water-safety plan approach promoted by WHO (26). A hydrogeological study was carried out to investigate the distribution of groundwater and the extension and flow velocity of the contamination plume. These data eventually allowed for estimations of the duration of contamination, which dated back more than 20 years. Soil monitoring showed a widespread presence of PFAS, not only in areas where human activity or erosion could have produced contamination, but also in those assumed to be free of it. Of 14 soil samples taken in the summer of 2016, half were found to have PFOA values higher than the threshold. Levels of PFAS in water from other industrial sources than the chemical plant were also measured but found to be considerably lower than those in water from the plant

[SNIP]

Occupational retrospective cohort study of employees at the chemical plant Currently, out of a total of approximately 600 employees at the chemical plant, 130 work in the production department, the pilot plant, the laboratory and the waste-processing area. The probable long-term effects of PFOA exposure on the health of 415 male employees, including former employees, were examined through a retrospective cohort mortality study (1975–2016). The study looked at all-cause mortality and mortality from diseases of the circulatory system, malignant neoplasms, cirrhosis and diabetes. The sera of a group of employees have been measured for PFOA contamination since 2000; in 2004–2012, the levels of those working in the PFAS production departments were steady. Mortality rates were higher for those exposed to PFOA and excess rates of liver, bladder and kidney cancer and cirrhosis were also observed for this group. Excess rates of cirrhosis, diabetes and hypertension were observed among all employees though they were higher among those exposed to PFOA (30)

POISONING THE ENVIRONMENT WUHAN

.. Some previous studies have also reported the occurrence of PFASs, especially PFOA and PFOS in river water globally

(Hansen et al., 2002;Mclachlan et al., 2007;Murakami et al., 2008;Yeung et al., 2009;Nakayama et al., 2010;Hong et al., 2013;Wang et al., 2013;Zhang et al., 2013).

In general, the PFAS concentrations in the Yangtze River were lower than those in other rivers in the world. ...

... This suggests widespread use of PFASs in industrial applications in these two cities. There are dozens of major industries, including fluorochemical, food pro- cessing, textiles, insecticides, pharmaceutical, and electroplating located in Wuhan ( Zhou et al., 2013;Wang et al., 2013), which could be the potential pollution sources. Wang et al. (2013) reported PFASs contami- nation in the effluents of a manufacturing plant in Wuhan, being respon- sible for the high PFAS concentration in the surrounding river water. ...

... There are dozens of major industries, including fluorochemical, food pro- cessing, textiles, insecticides, pharmaceutical, and electroplating located in Wuhan ( Zhou et al., 2013;Wang et al., 2013), which could be the potential pollution sources. Wang et al. (2013) reported PFASs contami- nation in the effluents of a manufacturing plant in Wuhan, being respon- sible for the high PFAS concentration in the surrounding river water. High concentrations of PFASs, especially thousands ng/L of PFBA (max concentration 47800 ng/L) and PFBS (max concentration 15 300 ng/L), were observed in surface water near a fluorochemical plant in Wuhan ( Zhou et al., 2013).

Animal-related poison experiments and human epidemiological studies have revealed PFC adverse effects, such as hepatotoxicity, immunotoxicity, developmental and reproductive toxicity, hormonal effects and carcinogenic potency9,10,11,12. In recent years, PFCs have been frequently detected in various environmental waters and strongly proved to accumulate in aquatic biotas, which makes the aquatic ecosystem as an important medium for PFC transport.

[SNIP]

Occurrence investigation of PFCs in surface water from East Lake

The East Lake, located in Wuhan city, is the second largest urban lake in China, with a total water area of 33 km2 and an average depth of 2.5 m. A number of enterprises, hospitals and communities are built around the lake, which makes it very important for industrial production, life of local residents and tourist entertainment. However, during the past decades, with the rapid industrialization and urbanization, chemical pollutants were continuously discharged into the lake that has no dilution ability due to its closed shape.

Presently, the existence of PFOS and PFOA in East Lake has been proved by researchers.

[SNIP]

the PFCs in surface water from East Lake were accurately and sensitively determined by the proposed MSPE-UPLC-MS/MS method. The surface water had a widespread contamination of PFCs with PFOS and PFOA as the most prevalent pollutants, and the Niuchao lakelet was loaded with the greatest PFC pollutions attributed to more human activities.

Nature

At a time of unprecedented human need, DuPont scientists, engineers, and countless employees are working together to deliver solutions to combat the COVID-19 pandemic.

OH THE IRONY...suits you, sir!

dupont in wuhan

THEY MAKE THE PROTECTIVE SUITS

"Thousands of DuPont employees are working around the clock to increase production of protective garments that are in high demand by first responders and medical workers in high-impact regions like Wuhan, China.

The protective suits are used by health professionals during the outbreaks to reduce the risk of infection. Reports from China show workers running low on safety supplies including garments and masks."

[SNIP}

"Of the protective suits DuPont makes, the most popular is the white Tyvek suit, which costs anywhere between $5 to $15. The suit is thin and protects the body from many fluids, but does not cover the hands, feet or face. But it also makes heavy duty Hazmat suits that act as a shell around the entire body, and are often worn with an oxygen tank.

Those suits can cost in many cases more than $1,000."

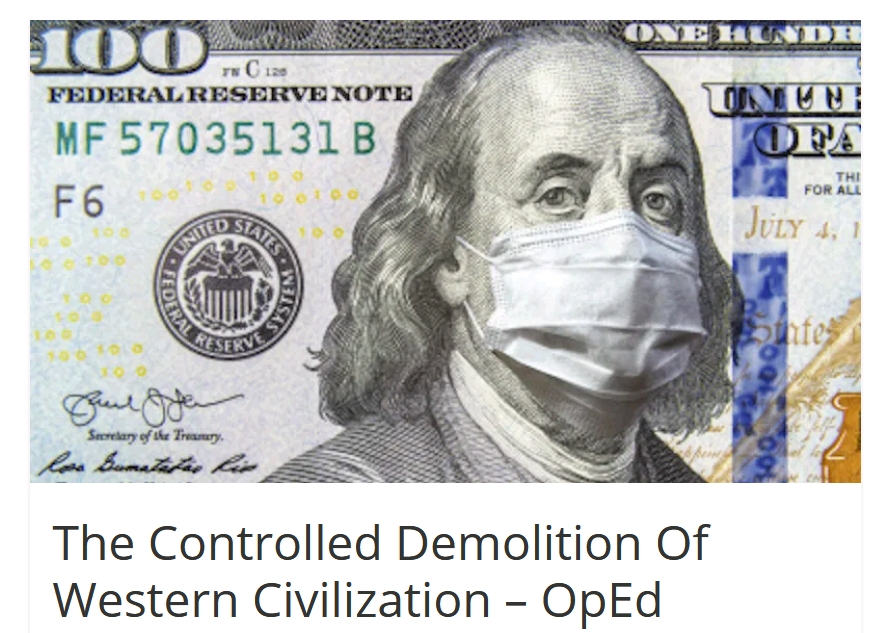

Mask Pollution...helping the U.N Sus Dev goals?

Conservationists have warned that the coronavirus pandemic could spark a surge in ocean pollution – adding to a glut of plastic waste that already threatens marine life – after finding disposable masks floating like jellyfish and waterlogged latex gloves scattered across seabeds.

The French non-profit Opération Mer Propre, whose activities include regularly picking up litter along the Côte d’Azur, began sounding the alarm late last month.

Divers had found what Joffrey Peltier of the organisation described as “Covid waste” – dozens of gloves, masks and bottles of hand sanitiser beneath the waves of the Mediterranean, mixed in with the usual litter of disposable cups and aluminium cans.

The quantities of masks and gloves found were far from enormous, said Peltier. But he worried that the discovery hinted at a new kind of pollution, one set to become ubiquitous after millions around the world turned to single-use plastics to combat the coronavirus. “It’s the promise of pollution to come if nothing is done,” said Peltier.

We want to hear about the things you are doing to help protect your ocean. You can get in touch by filling in the form below. Only the Guardian can see your contributions and one of our journalists may contact you to discuss further.

In France alone, authorities have ordered two billion disposable masks, said Laurent Lombard of Opération Mer Propre. “Knowing that … soon we’ll run the risk of having more masks than jellyfish in the Mediterranean,” he wrote on social media alongside video of a dive showing algae-entangled masks and soiled gloves in the sea near Antibes.

The group hopes the images will prompt people to embrace reusable masks and swap latex gloves for more frequent handwashing. “With all the alternatives, plastic isn’t the solution to protect us from Covid. That’s the message,” said Peltier.

In the years leading up to the pandemic, environmentalists had warned of the threat posed to oceans and marine life by skyrocketing plastic pollution. As much as 13 million tonnes of plastic goes into oceans each year, according to a 2018 estimate by UN Environment. The Mediterranean sees 570,000 tonnes of plastic flow into it annually – an amount the WWF has described as equal to dumping 33,800 plastic bottles every minute into the sea.

These figures risk growing substantially as countries around the world confront the coronavirus pandemic. Masks often contain plastics such as polypropylene, said Éric Pauget, a French politician whose region includes the Côte d’Azur.

“With a lifespan of 450 years, these masks are an ecological timebomb given their lasting environmental consequences for our planet,” he wrote last month in a letter to Emmanuel Macron, calling on the French president to do more to address the environmental consequences of disposable masks.

Earlier this year the Hong Kong-based OceansAsia began voicing similar concerns, after a survey of marine debris in the city’s uninhabited Soko Islands turned up dozens of disposable masks.

“On a beach about 100 metres long, we found about 70,” said Gary Stokes of OceansAsia. One week later, another 30 masks had washed up. “And that’s on an uninhabited island in the middle of nowhere.”

Microplastics found in greater quantities than ever before on seabed

Curious to see how far the masks had travelled, he began checking other nearby beaches. “We’re finding them everywhere,” he said. “Ever since society started wearing masks, the cause and effects are being seen on the beaches.”

While some of the debris could be attributed to carelessness, he speculated that the lightweight masks were at times also being carried from land, boats and landfills by the wind.

“It’s just another item of marine debris,” he said, likening the masks to plastic bags or straws that often wash up on the city’s more remote shorelines. “It’s no better, no worse, just another item we’re leaving as a legacy to the next generation.”

Still, given the likelihood that porpoises and dolphins in the region could mistake a mask for food, he was bracing himself for a grim find. “We’re constantly getting them washing up dead and we’re just waiting for a necropsy when we find a mask inside,” he said. “I think it’s inevitable.”

June 2020 - WEF reports on Pollution by PPE

Between the end of February and mid-April this year more than a billion items of personal protective equipment were given out in the UK alone.

That’s millions of gloves and masks being used then thrown away every single day - just in UK healthcare settings. So it’s not difficult to see why conservationists around the world are sounding the alarm over where all these single-use products are ending up.

Waterlogged masks, gloves, hand sanitizer bottles and other coronavirus waste are already being found on our seabeds and washed up on our beaches, joining the day-to-day detritus in our ocean ecosystems.

why aren't they being treated as a biorisk? & disposed of properly?

This really is a no brainer

About 1.56 billion masks will enter oceans in 2020, which amounts to between 4,680 and 6,240 metric tonnes of plastic pollution, a Hong Kong-based environmental group OceanAsia has said. These masks will take as long as 450 years to break down and all the while serve as a source of micro plastic and negatively impact marine wildlife and ecosystems, the group, in its latest report 'The impact of Covid-19 on marine plastic pollution', has said.

OceanAsia says from a global production projection of 52 billion masks made in 2020, "conservatively" speaking, at least 3 per cent will enter the seas.

The use of PPE, in particular face masks, and to a lesser extent gloves and face shields, has become widespread and a common tool used in preventing the spread of the pandemic. The value of the global face masks market was $0.79 billion in 2019, but expanded to an estimated $166 billion by the end of 2020, says OceanAsia.

"World leaders and politicians are aware of the problem -

WEF

COVID-19’s cost to the environment

Single-use plastic waste is not the only impact COVID-19 is having on the environment.

Despite a temporary crash in carbon emissions as lockdowns have meant fewer people travelling and less industrial activity, there are concerns the pandemic will divert governments’ attention away from green issues.

The UN’s COP26 climate change conference, set to be held in November 2020, has already been postponed.

In some US cities, recycling programmes have been paused, while parts of virus-hit Italy and Spain also put a hold on recycling.

The quarantine economy has driven more people online, resulting in greater packaging waste from deliveries. Medical waste has rocketed.

Import and export restrictions, as well as declines in the availability of cargo transportation, mean that large amounts of food have also gone to waste. And as this organic waste decays it will release greenhouse gases.

And unless economic stimuli focus on green initiatives, there is a risk of a sudden upsurge in polluting activity as construction and manufacturing are used to drive recovery from the global downturn the virus has created.

“Let this moment be a wake-up call for all of us,” Goldsmith says. “As countries emerge from the pandemic, we will all have to find ways to rebuild and to renew.

“And I think that gives us a one-off huge opportunity to choose a different path - one that ensures environmental sustainability and resilience are the lens through which we make decisions and map out our recovery.”

destroy & rebuild

What we are witnessing during this “corona-crisis” is simply unprecedented. It is nothing short of a blatant attempt to destroy the private sector, the capitalist system and the financial sovereignty of every citizen. The state denies the right of every individual to work, to put food on the table, to provide for their families and to take personal responsibility for their own choices. On a societal level, is nothing less than the transformation into a technocratic, big data “new normal” that already exists in China and this Orwellian nightmare is already our new and sad reality. -

And so the World Economic Forum website itself announces in its headline: “Now is the Time for a Great ‘Reset’.” No secret conspiracy there, for Klaus Shwab himself tells it how it is from the inside. Such things have been discussed for many years before COVID, of course, in the UN’s Agenda21 and Agenda2030, for example. They have been set forth as policies, rather than as mere aspirations. And so they require something to make them happen apart from wishful thinking. But the tone of the WEF article is that COVID gives an ideal opportunity to make them happen now, to the benefit of all, etc. But note that the basis is “stakeholder capitalism,” and that the article neglects to say who the stakeholders profiting from it may be, whilst only vaguely talking of fairness and sustainability for all.

The identity of the beneficiaries is not hard to answer, because those participating in the WEF are not the disempowered ordinary people of the world, but global capitalists who, so far, have shown a great propensity for making money through their disproportionate influence on global institutions, rather than for redistributing their wealth through encouraging competition from the little guys.

Note, for one prominent example, how the Gates Foundation has major influence over the WHO, governments including our own, academic institutions and NGOs like the WEF (whose “Global Fund” it has financed to the tune of $1.5bn).

I'm starting to wonder what these Stakeholder Capitalists mean by the notion of sustainable development...

Because if massive corporations who are both bioscience and polluter can generate illness via the by-products of the myriad of chemical filled product... [safety equipment included for irony]...and the governments of the world via WEF / UN steering can implement a Circular economy...

it would appear that illness / disease would be a useful thing to be able to control. or should i say; manage.

Control the cause of disease

Control the cure...

a continually suffering humanity

Smartphones hit with chip shortage

Chipageddon: The Chip Shortage in ~1500 Words

Renana Ashkenazi - Jul 13

CCSI International is a family-run company from rural Illinois that makes electronic dog-washing booths. All they need is soap, water, and a dirty pet — and, well, some computer chips to control their machines. Oh boy. With Jaguar, Ford, Subaru, and Toyota shutting down factories and laying off workers, what chance do the pets stand?

Unless you’ve been living under a rock, you must have heard about the chip shortage. By now there’s even a Wikipedia page for the 2020–2021 global chip shortage — so you know it’s a real thing.

But why is this happening, who should care, how does it affect semiconductors founders, and are there any signs of relief?

Why Now?

Well, let’s start from the obvious: if someone wants something and there isn’t enough of it, that means that someone (else) miss-calculated supply and demand balance. And indeed, the shortage stems from some severe miss-calculation of demand on the world’s chipmakers' side — all are now overwhelmed by a sharp increase in demand.

Let’s see: we had a pandemic, causing supply chain problems all across the globe. If that wasn’t enough, the blocking of the Suez Canal, one of the world’s busiest trade routes connecting Europe and Asia caused a jam of hundreds of cargo ships in March, and the February Texas storm that forced Samsung, NXP Semiconductors, and Infineon to shut down factories temporarily. The Taiwan drought (fabs are huge water consumers) didn’t help and a fire last March in the Renesas chip factory in Japan, manufacturing 2/3 of the automotive industry chips, significantly impacted the entire supply chain. Add to that the fact that there is a tight geographic concentration of supply chain and of course the trade war between the US and China isn’t helping — it seems the god of Semiconductors are angry.

COVID-19: If there’s one good thing about COVID, it’s that you can blame it for just about anything. The remote-everything trend fueled by lockdowns increased sales of computers and other electronic devices on one hand (not only does every employee now require a laptop, but it also must be a stronger model to support virtual- everything), while the automotive industry witnessed a dip in demand that wasn’t expected to change in the short term: No one was going anywhere. As a low margin industry, the automotive industry sticks to a “just-in-time” manufacturing policy as opposed to “just in case” philosophy: our ability to track down to the minute the global movement of ships and trucks enables manufacturers to ensure that just the part they need arrive exactly when needed, reduce redundant costs, and increase efficiency. But it also means there’s very little room for error. Or for a global pandemic. So, chipmakers switched over their production lines from the automotive lines, which meant that in Q3 2020, when demand for consumer electronics continued to grow but sales of cars came soaring back unexpectedly, the demand could not be met.

Geographic Concentration

The semiconductor industry is a highly specialized global supply chain. Each region performs its part based on its comparative advantage, with over 50 points across the supply chain where one region holds over 65% of the global market share. While the US, with its world-class education system and an abundance of engineering talent, leads in core IP and chip design, east Asia took the lead in wafer fabrication, which requires massive capital investment supported by government incentives. Based on a BCG report from April 2021, 100% (!!) of the world’s most advanced semiconductor manufacturing capacity (below 10nm) is currently located in South Korea (8%) and Taiwan (92%). China, on its end, ruled in assembly, packaging, and testing.

This model did not only work well, it also saved a lot of money. But it clearly suffers from its vulnerabilities as it relies on free trade compromised by geopolitics tension, mother nature, and your current global virus.

Geopolitics

When the US government restricted technology exports to China, some Chinese manufacturers have been stockpiling, preparing for further restrictions. Huawei, for example, used to be one of the industry’s biggest chip buyers. In anticipation of being put on a US trade blacklist (which indeed it was, followed recently by Xiaomi), it began stockpiling chips from 2019, which led to tight capacity at Huawei’s main chip supplier, TSMC. Trump’s restrictions on SMIC also meant that companies had to shift to other manufacturers increasing the bottleneck.

Who Cares?

In short, everyone. The world runs on microchips, and not just the obvious ones in our phones or computers (which by itself means that half the world population should care — a recent study by strategy analytics claims that 4 billion people own a smartphone). Our shopping experience, our health system experience, our driving experience, and our learning experience — every aspect of our day-to-day is becoming more digital. And when it becomes digital, it runs on semiconductors.

The first to take a hit was the automotive industry — new cars typically include dozens of microprocessors. Ford, BMW, Volkswagen, have all reported bottlenecks in manufacturing, some carmakers are leaving out high-end features (Nissan, for example, is reportedly leaving navigation systems out of some of its cars. If you’re anything like me, that hurts). But recently, electronics manufacturers in Asia have also warned that the chip shortage was beginning to spread to consumer electronics and home appliances.

How Will I be Affected as a Semiconductors Startup Founder?

As a tech-savvy fund, Grove Ventures has a pretty wide semiconductor portfolio. The picture as it is painted by our founders is consistent: It’s not only that fabs’ willingness/ability to invest in R&D (as opposed to production) is at an all-time low, but also that price and timeline of just about everything are impacted. If you’re selling a development kit, your capacitors, resistors, boards, FPGA’s, all of these parts are now more expensive if you’re lucky, or out of stock (with a year-and-a-half lead time) if you’re not. That means your BOM changes and you’re back at the drawing board for some significant redesign. A large corporate executive I spoke with last week said that 40% (!!) of his R&D is busy with redesign. What can you do? Overstock (if you think you’ll need 20 kits, plan for at least double. This way, even if your supplier reallocates and cuts your supply by half, you’re still good. You’re also prepared for positive traction), be as creative as possible with your sourcing, and be mentally ready for some major changes in design.

Who’s Enjoying The Situation?

In face of demand — we pay. So not surprisingly, the revenues of the 10 semiconductor foundries broke records in Q1 reaching $22.75B with TSMC holding a phenomenal 55% market share. And of course, if you are a semiconductor investor, you’re also in luck. The SOX index (composed of companies primarily involved in the design, distribution, manufacture, and sale of semiconductors) has increased 14% since the beginning of the year (compared to a 7.7% increase in the technology sector of the S&P 500 index).

When Will This End??

Well, it depends on who you ask. Some manufacturers forecast the shortage will last until at least mid-2022. Flex, for example, the world’s third-biggest electronics contract manufacturer, said that the manufacturers it relies on for semiconductors have pushed back their forecasts for when the shortage will end. Some of the more pessimistic analysts (Forrester, for example) believe the shortage could last until 2023. The most optimistic estimation I could find was by Cisco’s CEO expecting a relief by early 2022. What we know for sure is that the only realistic solution is to increase the supply of semiconductors, and indeed — it’s response time.

Response Time

Chipmakers are investing more and more in new production capacity: Intel announced in March that it plans to spend $20 billion on two new chip factories in Arizona. TSMC announced in April it plans to invest $100 billion in the next three years in expanding its manufacturing capacity and GlobalFoundries announced in June a $6B expansion in Singapore, the US, and Germany.

Many car companies have adopted a more assertive approach to sourcing, such as stocking and paying for chips in advance, and some are being more creative. Tesla, as the Elon-company that it is, has been reported to explore buying a chip plant outright. Bosch, Europe’s largest auto parts supplier, opened a $1.2B chip factory in Dresden last June, the single largest investment in the company’s history.

Countries are trying to become more independent when it comes to semiconductor production. The US is upping its game. The US Senate just recently passed a bill to support domestic chip production in the US. Just this March, Biden called on Congress to invest $50 billion in semiconductor manufacturing and research to support the CHIPS Act (Creating Helpful Incentives to Produce Semiconductors. Masterpiece of copywriting). Immediately following Biden’s statement, a cross-sector alliance of semiconductor companies and major downstream users of semiconductors (from the immediate suspects such as AMD, Intel, IBM Nvidia to AWS, Apple, Google, and Microsoft) announced the formation of the Semiconductors in America Coalition (SIAC) and called on congressional leaders to allocate $50 billion for domestic chip manufacturing incentives and research initiatives.

The EU’s updated its industrial strategy, now including semiconductor technologies as an area of key vulnerability for Europe’s strategic interests and declaring that the EU should produce more chips locally to help prevent future supply issues. In response, Intel announced in March that it will open a foundry plant for cutting-edge semiconductors in Europe.

There’s no reason for the demand for semiconductors to slow down (cloud computing growth, cryptocurrency mining, 5G, AI, and the list goes on and on), and having 80% of its supply concentrated in a single region should probably have never made sense in the first place (never put all your eggs in one basket and all that). The only realistic solution is geographic diversification and increasing the supply of semiconductors. There is, however, a place for optimism — billions are being spent to shorten the waitlist for my new Playstation5.

flashback: Exposure to Glycol Ethers...

IBM chip manufacturing is cancer factory

The women on the production line worked in so-called cleanrooms and wore protective suits, but that was for the chips’ protection, not theirs. The women were exposed to, and in some cases directly touched, chemicals that included reproductive toxins, mutagens, and carcinogens. Reproductive dangers are among the most serious concerns in occupational health, because workers’ unborn children can suffer birth defects or childhood diseases, and also because reproductive issues can be sentinels for disorders, especially cancer, that don’t show up in the workers themselves until long after exposure.

[snip]

Gordon Moore, a founder of Intel and a major figure in the creation of the modern chip in 1960, is a chemist. He worked closely on the printing process with a physicist named Jay Last. “We were putting into industrial production a lot of really nasty chemicals,” Last said in an interview he did with Moore for an oral history project of the Chemical Heritage Foundation. “There was just no knowledge of these things, and we were pouring stuff down into the city sewer system.”

Moore recalled how, years later, when workers dug up the pipes beneath Intel, they discovered the “bottom was completely eaten out the whole way along, and that was just about the time we really started recognizing how much you had to take care of this.” Authorities would end up designating more Superfund hazardous waste sites in Santa Clara County, the heart of Silicon Valley, than in any other county in the U.S.

As Kim learned in her scientific review, one critical chemical cocktail in the printing process is called a photoresist. It’s a light-sensitive compound that allows circuit patterns to be photographically printed on the chips. Moore and Last suggested in their oral-history interview that the dangers of the chemicals they were using were unknown in 1960, but studies linking photoresist ingredients to dangers dated to the 1930s. The toxic ingredients were called ethylene glycol ethers, or EGEs. They also became key ingredients in solvent mixtures known as strippers, which are used to clean the chips during printing.

Park Min-sook worked for seven years at a Samsung semiconductor plant. She later suffered infertility and a miscarriage, and then was diagnosed with breast cancer.

“I had a friend in Bay 1 who was infertile for seven years. There was a girl in Bay 2 who was infertile for 10 years. I was infertile for four years, and I had one miscarriage. That’s so strange, why was that? Why were all these people having thyroid problems and cancers? It struck me that it wasn’t just coincidence.

Would you like to see a wafer? Interviewers love seeing this. The tiny ones were cute, so I snuck a rejected one out. This was in the ’90s. I don’t even want to touch it. Someone once told me to take a picture holding it with my hand, and I was like, never again.”

Kim could see that Pastides pointed to these same chemicals when he did his study at Digital Equipment, as did the Johns Hopkins scientists working with IBM. The IBM study found miscarriage rates tripled for women who worked specifically with EGEs. Separate studies showed EGEs easily permeated rubber gloves, like water through a net, and that skin absorption was the most dangerous route, leading to exposure rates 500 to 800 times above the level deemed safe. The dangers were so abundantly clear that the U.S. Occupational Safety and Health Administration in 1993 formally proposed exposure levels so minute that, practically speaking, companies would have to ban EGEs to comply.

Kim’s study took her through not only all of that research but also the studies done since. Historical reproductive-health studies connected microelectronics production to fatal birth defects in the children of male workers, childhood cancers among the children of female workers, and infertility and prolonged menstrual cycles.

Bloomberg

Occupational Exposure to GlycolEthers

PDF report

Phenoxyethanol is the organic compound with the formula C6H5OC2H4OH. It is a colorless oily liquid.

It can be classified as a glycol ether and a phenol ether.

It is a common preservative in vaccine formulations

Safety review of phenoxyethanol when used as a preservative in cosmetics

It has a large spectrum of antimicrobial activity and is effective against various Gram-negative (e.g. Pseudomonas aeruginosa) and Gram-positive (e.g. Staphylococcus aureus)1 bacteria, as well as against yeasts (e.g. Candida albicans).2, 3 Phenoxyethanol exerts its antimicrobial activity by uncoupling oxidative phosphorylation from respiration and by competitively inhibiting malate dehydrogenase.4

It also acts as a bactericidal agent by increasing the permeability of the cell membrane to potassium ions and exerts a direct inhibitory effect on microbial DNA and RNA synthesis.4

Due to its broad antimicrobial activity, phenoxyethanol has been used for decades as a preservative in various products such as medicines (e.g. in vaccines) and hand disinfecting biocidal products up to a concentration of 5%, including products for toddlers.5

What diseases are caused by Pseudomonas aeruginosa?

Pseudomonas aeruginosa is an opportunistic pathogen. The bacteria takes advantage of an individual's weakened immune system to create an infection and this organism also produces tissue-damaging toxins. Pseudomonas aeruginosa causes urinary tract infections, respiratory system infections, dermatitis, soft tissue infections, bacteremia, bone and joint infections, gastrointestinal infections and a variety of systemic infections, particularly in patients with severe burns and in cancer and AIDS patients who are immunosuppressed.

note:

The Santa Barbara County Coroner’s office reports Vaughan died from a bilateral pulmonary thromboembolism, which is usually when a blood clot travels into the lungs. - source

Puff piece for the Pharma Industry

What is polyethylene glycol and why is it in some COVID-19 vaccines?

Both the Pfizer and Moderna vaccines contain polyethylene glycol.

March 17, 2021

TAMPA, Fla. — You may have heard that some of the COVID-19 vaccines have Polyethylene glycol.

10 Tampa Bay spoke with Dr. Jill Roberts at USF Health to get you a sharper insight.

Roberts says it's used for "stabilizing", and the reason it's used in the Pfizer and Moderna vaccines is that the little piece of genetics that's creating the response we want is very unstable.

So the concern lies around whether polyethylene glycol, known as "P-E-G," is causing allergic responses. The reason is that it's the only component that's in the vaccine that's similar to anything that's caused an allergic response in the past.

"That's not necessarily bad news. What that means is if you know someone already has an allergic response, we know exactly which vaccines to avoid," says Dr. Roberts.

Polyethylene glycol is also found in several things you use every day: toothpaste, skin creams, and laxatives.

And remember, the FDA approval of the Pfizer and Moderna vaccines included a warning that people with allergic reactions should talk to their doctor about getting the vaccine.

The "glycol ethers" Industry

Glycol Ethers Market -

Growth, Trends, COVID-19 Impact, and Forecasts (2021 - 2026)

The market for glycol ethers is expected to register a CAGR of more than 5.5%, during the forecast period. The major factors driving the growth of the market studied are the increasing usage in cosmetics and personal care products, and accelerating demand in the paints and coatings industry. On the flipside, REACH and EPA regulations regarding the usage of glycol ethers, and the emergence of new products, like cellulosic ethanol, to use as a solvent for cleaning agents are restraining the growth of the market studied.

The paints and coatings segment dominated the market. It is expected to grow during the forecast period, with anticipated robust demand for paints and coatings from various industries, such as construction, packaging, etc.

The growing awareness leading to excess demand for P-series glycol, for low emission oxygenated diesel fuel, is likely to provide opportunities for the market studied, during the forecast period.

Asia-Pacific dominated the market across the globe due to the significant growth in demand and thereby, production in industries, such as paints & coatings, adhesives, and cosmetic & personal care.

Key Market Trends

Paints and Coatings Segment to Dominate the Market

Glycol ether helps in the formation of a proper film during coating cure and acts as an active solvent in resins. It helps in optimizing the evaporation rate of the solvent in a coating. It is also helpful in improving the flow out characteristics of the paint, and in eliminating brush marks during painting.

The paints and coatings industry is the largest consumer of glycol ethers. Paints and coatings are extensively used in various industries, such as construction, automotive, and packaging.

Residential and commercial construction has been increasing significantly across the world, which is driving the demand for glycol ethers, for their application in the production of architectural paints and coatings.

According to the World Bank, the construction industry expenditure in 2020 is likely to witness a growth of about 4.2% from 2019. This, in turn, is likely to increase the demand for glycol ether over the forecast period.

Asia-Pacific has been witnessing a growth of residential and commercial construction projects, due to growing housing needs, and noticeable growth opportunities prevailing in the region.

In the Middle East, the government's efforts to develop non-oil industries are leading to investments in industries, such as tourism, hospitality, healthcare, further driving the demand for, and investments in the commercial infrastructure.

North America also witnessed a noticeable increase in residential construction and renovation projects in the country. Steady economic recovery in Europe has triggered the construction activities in the region.

Additionally, in the global automotive industry, though production declined in 2018 by 1.1%, factors, such as increasing investments in the sector to increase production, continuous efforts of automakers to develop and launch new cars, and efforts toward development and promotion of electric vehicles of the industry, are likely to drive the growth of the automotive industry.

Hence, the aforementioned trends are likely to increase the demand and production in the paints and coatings market, which may further drive the demand for raw materials, like glycol ethers.

Asia-Pacific Region to Dominate the Market

The Asia-Pacific region dominated the market share. The demand for products, such as paints, coatings, and adhesives, has been increasing from the end-user industries, such as automotive, construction, electronics, and packaging.

Countries, such as India, China, the Philippines, Vietnam, and Indonesia, have numerous construction projects and investments planned, which may increase the demand for architectural paints, coatings, and adhesives.

Countries, such as India, Thailand, Vietnam, Pakistan, and Malaysia, have recorded noticeable growth in automotive production. China, the world’s largest automotive producer, has plans to increase the production of electric vehicles (EVs) to 2 million a year, by 2020, and 7 million a year by 2025.

Furthermore, in the cosmetics and personal care industry, the demand is increasing at a noticeable rate in the region, owing to the influence of western culture and increased cosmetic demand from the youth population. With this, the market players are increasing investments and production, thereby driving the demand for raw materials, including glycol ethers.

The pharmaceutical industry in India, South Korea, and ASEAN countries are witnessing huge investments from foreign countries, in order to exploit the market opportunities, which may increase the demand for glycol ethers in the region, during the forecast period.

Hence, such favorable market trends are likely to drive the growth of the glycol ethers market in the region, during the forecast period.

Competitive Landscape

The glycol ethers market is fragmented, with numerous players holding insignificant market share to affect the market dynamics individually. Some of the noticeable players in the market include BASF SE, Eastman Chemicals Company, Royal Dutch Shell, and Dow, among others.

Glycol Ethers Market - Growth, Trends, COVID-19 Impact, and Forecasts (2021 - 2026)

"A weakened immune system appears to be the main determinant of serious/fatal reaction to viral infection (for COVID-19, SARS, and influenza alike). "

it's a Scamdemic!

AQUIRING HIDDEN COMPANIES IN THE PHARMACEUTICAL AREA?

TO HIDE ITS PRACTICES AFTER BAD PRESS?

Location: Just Outside Milan, Northern Italy

only rolled out in March 2020 -

by June this was in the mainstream...

Mon 8 Jun 2020 -

and that it needs to be addressed."

"The quarantine economy"

has been discussed by

the Pigs around the trough....

as a cash cow...a golden goose.

Enforced Scarcity

$$$ economic driver for price haul $$$

Pharmaceutical industry is poisoning - has vested interests in perpetual illness & disease